MILLIFOAM® Products

MILLIFOAM® Products

Choose your polymeer to get more information.

MILLIFOAM® PMI

MILLIFOAM® PVC

MILLIFOAM® PESU

MILLIFOAM® PEI

MILLIFOAM® PET

MILLIFOAM® PPSU

MILLIFOAM® PMI

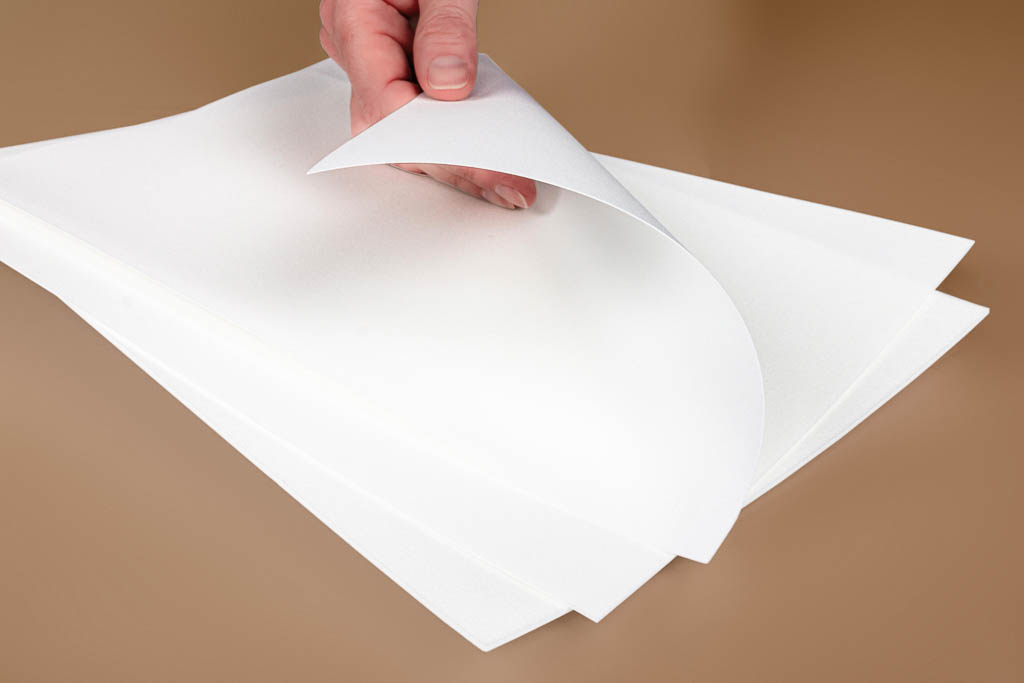

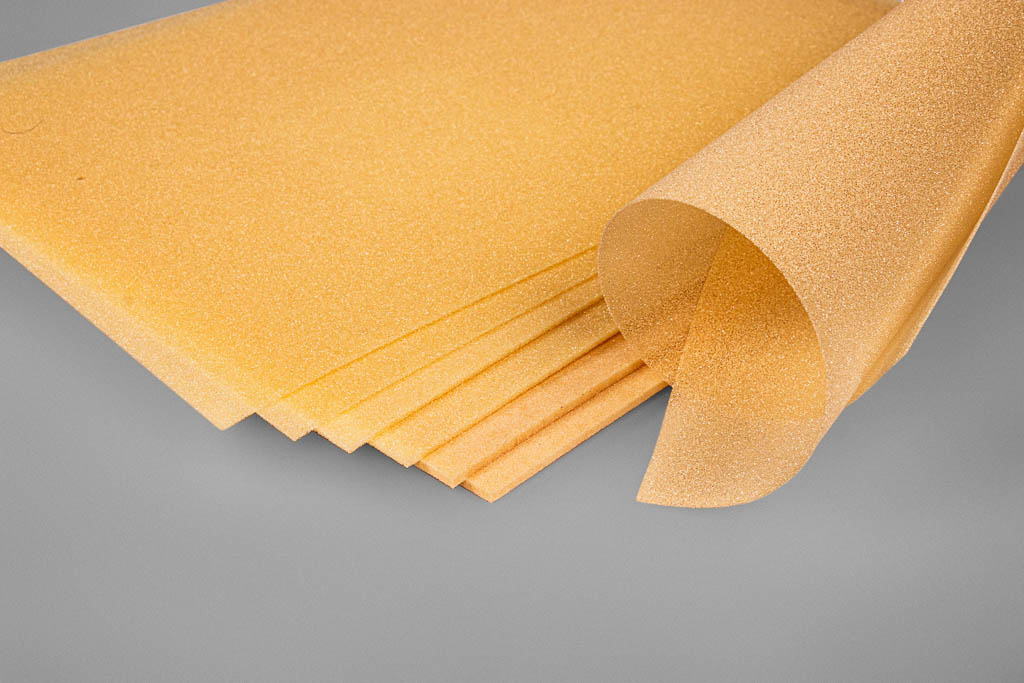

MILLIFOAM® Rohacell® IG-F - The Industrial Standard

With Rohacell® IG-F we provide the standard industrial grade from Evonik.

It is the foam of choice for automotive, watercraft, electronics, medical and other industrial applications. Additionally, it is a commonly used core material for x- ray and CT tabletops in the technology medical market.

Rohacell® IG-F is characterized by a fine cell structure and a minimal resin uptake at the surface, where the cells have been gentle cut open with our MILLIFOAM® slicing technology. Less resin uptake during part processing means lower final part weight and reduced overall cost.

MILLIFOAM® Rohacell® IG-F thin hard foam sheets give maximum freedom in design, because it can be thermoformed and tailored into complex high-precision geometries with the 4a MILLIFOAM® Shaping service.

It is suitable for prepreg processing, resin infusion and RTM process up to temperatures of 130°C (266°F) and pressures of 0.3 MPa (44 psi).

| Physical Characteristics | ||||

|---|---|---|---|---|

| Format | MILLIFOAM® RHC31IGF |

MILLIFOAM® RHC51IGF |

MILLIFOAM® RHC71IGF |

|

| Plain Sheet | ||||

| Length (mm) | 2500 | 2500 | 2500 | |

| Width (mm) | 625 | 625 | 625 | |

| min. Thickness (mm) | 0.75 | 1.00 | 0.50 | |

| max. Thickness (mm) | 3.00 | 3.00 | 3.00 | |

| Standard thickness tolerance ±10%, other tolerances available on request. | ||||

| Mechanical Characteristics | |||

|---|---|---|---|

| Property | MILLIFOAM® RHC31IGF |

MILLIFOAM® RHC51IGF |

MILLIFOAM® RHC71IGF |

| Density (kg/m³) | 32 (±7) | 52 (±12) | 75 (±15) |

| Test Method: ISO 845 ASTM D 1622 | |||

| Compressive Strength (MPa) | 0.4 | 0.9 | 1.5 |

| Test Method: ISO 844 ASTM D 1621 | |||

| Compressive Modulus (MPa) | 17 | 43 | 73 |

| Test Method: ISO 844 ASTM D 1621 | |||

| Tensile Strength (MPa) | 1.0 | 1.9 | 2.8 |

| Test Method: ISO 527-2 ASTM D 638 | |||

| Tensile Modules (MPa) | 36 | 70 | 92 |

| Test Method: ISO 527-2 ASTM D 638 | |||

| Shear Strength (MPa) | 0.4 | 0.8 | 1.3 |

| Test Method: DIN 53294 ASTM C 273 | |||

| Shear Modules (MPa) | 13 | 19 | 29 |

| Test Method: DIN 53294 ASTM C 273 | |||

MILLIFOAM® Rohacell® HF – The Dielectric Leader

We offer Evonik’s high frequency foam grade Rohacell® with unique thickness.

Rohacell® HF is characterized by an extremely low dielectric constant and particularly favorable transmission properties in the high frequency region. This makes it to a favoured core material for the use in our CIMERA® micro-sandwich radomes for 5G mmWave small cell antennas, SatCom and SatCom on the move applications.

With our MILLIFOAM® technology, we provide Rohacell HF® in a unique thickness range starting from 0.5mm up to 3,0mm. In combination with a tight thickness tolerance and MILLIFOAM® superior surface quality, Rohacell® HF is the ideal choice for e.g. substrates or dielectric spacers in mobile and stationary antennas.

The ultrafine closed cell structure allows a minimal resin uptake and a good compatibility with metallic materials due to the absence of corrosive effects.MILLIFOAM® Rohacell® HF thin hard foam sheets give maximum freedom in design, because it can be thermoformed and tailored into complex high-precision geometries by the 4a MILLIFOAM® Shaping service. It is suitable for hand lay- up, prepreg processing and vacuum infusion at temperatures up to 130°C (266°F) and pressures up to 0.3 MPa (44 psi).

| Physical characteristics | ||||

|---|---|---|---|---|

| Format | MILLIFOAM® RHC31HF |

MILLIFOAM® RHC51HF |

MILLIFOAM® RHC71HF |

|

| Plain Sheet | ||||

| Length (mm) | 2500 | 2500 | 2500 | |

| Width (mm) | 625 | 625 | 625 | |

| min. Thickness (mm) | 0.5 | 0.5 | 0.5 | |

| max. Thickness (mm) | 3.00 | 3.00 | 3.00 | |

| Standard thickness tolerance ±10%, other tolerances available on request. | ||||

| Mechanical Characteristics | |||

|---|---|---|---|

| Property | MILLIFOAM® RHC31HF |

MILLIFOAM® RHC51HF |

MILLIFOAM® RHC71HF |

| Density (kg/m³) | 32 (±7) | 52 (±12) | 75 (±15) |

| Test Method: ISO 845 ASTM D 1622 | |||

| Compressive Strength (MPa) | 0.4 | 0.9 | 1.5 |

| Test Method: ISO 844 ASTM D 1621 | |||

| Tensile Strength (MPa) | 1.0 | 1.9 | 2.8 |

| Test Method: ISO 527-2 ASTM D 638 | |||

| Tensile Modules (MPa) | 36 | 70 | 92 |

| Test Method: ISO 527-2 ASTM D 638 | |||

| Shear Strength (MPa) | 0.4 | 0.8 | 1.3 |

| Test Method: DIN 53294 ASTM C 273 | |||

| Shear Modules (MPa) | 13 | 19 | 29 |

| Test Method: DIN 53294 ASTM C 273 | |||

| Electrical Characteristics | ||||

|---|---|---|---|---|

| Property | Frequency (GHz) | MILLIFOAM® RHC31HF |

MILLIFOAM® RHC51HF |

MILLIFOAM® RHC71HF |

| Dielectric Constants | 2.5 | 1.050 | 1.057 | 1.075 |

| 5.0 | 1.043 | 1.065 | 1.106 | |

| 10.0 | 1.046 | 1.067 | 1.093 | |

| 26.5 | 1.041 | 1.048 | 1.093 | |

| Loss Tangent | 2.5 | <0.0002 | <0.0002 | <0.002 |

| 5.0 | 0.0016 | 0.0008 | 0.0016 | |

| 10.0 | 0.0017 | 0.0041 | 0.0038 | |

| 26.5 | 0.0106 | 0.0135 | 0.0155 | |

MILLIFOAM® Rohacell® Rima – The Finest Grade

With Rohacell® Rima we provide Evonik’s finest PMI grade in class.

Rohacell® HF is characterized by an extremely low dielectric constant and particularly favorable transmission properties in the high frequency region. This makes it to a favoured core material for the use in our CIMERA® micro-sandwich radomes for 5G mmWave small cell antennas, SatCom and SatCom on the move applications.

With our MILLIFOAM® technology, we provide Rohacell HF® in a unique thickness range starting from 0.5mm up to 3,0mm. In combination with a tight thickness tolerance and MILLIFOAM® superior surface quality, Rohacell® HF is the ideal choice for e.g. substrates or dielectric spacers in mobile and stationary antennas.

The ultrafine closed cell structure allows a minimal resin uptake and a good compatibility with metallic materials due to the absence of corrosive effects.MILLIFOAM® Rohacell® HF thin hard foam sheets give maximum freedom in design, because it can be thermoformed and tailored into complex high-precision geometries by the 4a MILLIFOAM® Shaping service. It is suitable for hand lay- up, prepreg processing and vacuum infusion at temperatures up to 130°C (266°F) and pressures up to 0.3 MPa (44 psi).

| Physical Characteristics | |||

|---|---|---|---|

| Format | MILLIFOAM® RHC71RI |

MILLIFOAM® RHC110RI |

|

| Plain Sheet | |||

| Length (mm) | 2500 | 2160 | |

| Width (mm) | 625 | 550 | |

| min. Thickness (mm) | 0.5 | 0.5 | |

| max. Thickness (mm) | 3.00 | 1.00 | |

| Standard thickness tolerance ±10%, other tolerances available on request. | |||

| Mechanical Characteristics | ||

|---|---|---|

| Property | MILLIFOAM® RHC71RI |

MILLIFOAM® RHC110RI |

| Density (kg/m³) | 75 | 110 |

| Test Method: ISO 845 ASTM D 1622 | ||

| Compressive Strength (MPa) | 1.7 | 3.6 |

| Test Method: ISO 844 ASTM D 1621 | ||

| Tensile Strength (MPa) | 2.2 | 3.7 |

| Test Method: ISO 527-2 ASTM D 638 | ||

| Tensile Modules (MPa) | 105 | 180 |

| Test Method: ISO 527-2 ASTM D 638 | ||

| Shear Strength (MPa) | 1.3 | 2.4 |

| Test Method: DIN 53294 ASTM C 273 | ||

| Shear Modules (MPa) | 42 | 70 |

| Test Method: DIN 53294 ASTM C 273 | ||

MILLIFOAM® Rohacell® Hero – The Aircraft Standard

With Rohacell® Hero we provide Evonik’s standard in aircraft.

Rohacell® Hero is qualified by AIRBUS under AIMS 04-11-011 and ABS5955 standard for aircraft structural parts.

With this qualification and in combination with its outstanding mechanical behaviour, it is the recommended core material in composite structures for aircraft wings, landing gear doors, radomes, vertical and horizontal stabilizers, ailerons and other areas subjected to surface impact damage.

Compared to other core materials, Rohacell® Hero has excellent elongation at break properties and less water ingress, which is important to withstand the flexural loads and mechanical stresses.

Rohacell® Hero has a medium cell structure to ensure good bonding and shear strength. In combination with our MILLIFOAM® technology, the cells on the surface have been gentle cut open and allow a minimized resin uptake only in the cut surface cells. This results in a lighter finished part weight, e.g. compared to traditional honeycomb structures.

With a heat resistance of up to 210°C (428°F), processing or curing temperatures can be increased which results in a significant reduction in total cycle time and faster component manufacturing.

No other foam core material offers such a wide variety of processing, including autoclave, resin infusion, RTM and VARTM processes.

MILLIFOAM® Rohacell® Hero thin hard foam sheets give maximum freedom in design, because it can be thermoformed and tailored into complex high-precision shapes by the 4a MILLIFOAM® Shaping service.

| Physical Characteristics | ||||

|---|---|---|---|---|

| Format | MILLIFOAM® RHC51HE |

MILLIFOAM® RHC71HE |

MILLIFOAM® RHC110HE |

|

| Plain Sheet | ||||

| Length (mm) | 2500 | 2500 | 2160 | |

| Width (mm) | 625 | 625 | 550 | |

| min. Thickness (mm) | 0.50 | 0.50 | 0.50 | |

| max. Thickness (mm) | 2.50 | 2.50 | 2.00 | |

| Standard thickness tolerance ±10%, other tolerances available on request. | ||||

| Mechanical Characteristics | |||

|---|---|---|---|

| Property | MILLIFOAM® RHC51HE |

MILLIFOAM® RHC71HE |

MILLIFOAM® RHC110HE |

| Density (kg/m³) | 52 | 75 | 110 |

| Test Method: ISO 845 ASTM D 1622 | |||

| Compressive Strength (MPa) | 0.6 | 1.1 | 2.5 |

| Test Method: ISO 844 ASTM D 1621 | |||

| Compressive Modulus (MPa) | 32 | 48 | 83 |

| Test Method: ISO 844 ASTM D 1621 | |||

| Tensile Strength (MPa) | 2.6 | 4.1 | 6.3 |

| Test Method: ISO 527-2 ASTM D 638 | |||

| Tensile Modules (MPa) | 82 | 123 | 189 |

| Test Method: ISO 527-2 ASTM D 638 | |||

| Shear Strength (MPa) | 0.7 | 1.3 | 2.3 |

| Test Method: DIN 53294 ASTM C 273 | |||

| Shear Modules (MPa) | 22 | 28 | 50 |

| Test Method: DIN 53294 ASTM C 273 | |||

MILLIFOAM® Rohacell® XT – The Tough Grade

With Rohacell® XT we provide Evonik’s grade for the toughest conditions.

Rohacell® XT is a closed-cell rigid foam preferably for aeronautic and aerospace applications.

The XT stands for extended temperature and makes it to one of the best suited core materials for extreme and demanding processing requirements. It can take curing temperatures up to 180°C (356°F) and pressures of 0.45 MPa (65 psi). These extreme tough properties make Rohacell® XT the ideal foam for the use with BMI resins, among other materials.

MILLIFOAM® Rohacell® XT thin foam sheets are suitable for autoclave, vacuum infusion, RTM and VARTM processes. The sheets can be easily thermoformed and with 4a MILLIFOAM® Shaping, it can be provided as high-precision, pre-shaped and ready-to-use foam core for complex geometries.

| Physical Characteristics | |||

|---|---|---|---|

| Format | MILLIFOAM® RHC71XT |

MILLIFOAM® RHC110XT |

|

| Plain Sheet | |||

| Length (mm) | 2500 | 2160 | |

| Width (mm) | 625 | 550 | |

| min. Thickness (mm) | 0.50 | 0.50 | |

| max. Thickness (mm) | 3.00 | 3.00 | |

| Standard thickness tolerance ±10%, other tolerances available on request. | |||

| Mechanical Characteristics | |||

|---|---|---|---|

| Property | MILLIFOAM® RHC71XT |

MILLIFOAM® RHC110XT |

|

| Density (kg/m³) | 75 | 110 | |

| Test Method: ISO 845 ASTM D 1622 | |||

| Compressive Strength (MPa) | 1.7 | 3.6 | |

| Test Method: ISO 844 ASTM D 1621 | |||

| Tensile Strength (MPa) | 2.2 | 3.7 | |

| Test Method: ISO 527-2 ASTM D 638 | |||

| Tensile Modules (MPa) | 105 | 180 | |

| Test Method: ISO 527-2 ASTM D 638 | |||

| Shear Strength (MPa) | 1.4 | 2.1 | |

| Test Method: DIN 53294 ASTM C 273 | |||

| Shear Modules (MPa) | 42 | 63 | |

| Test Method: DIN 53294 ASTM C 273 | |||

MILLIFOAM® Rohacell® SL – The Top Performer

With Rohacell® SL we offer another top performing foam grade from Evonik.

Super lightweight Rohacell® SL is the favourite choice for today’s demanding and high performing applications. It boasts outstanding mechanical properties, especially tensile strength and a high tenacity. This makes it to the foam core of choice for applications with substantial dynamic mechanical loads.

The fine cell structure of Rohacell® SL also allows to minimize the resin uptake while maintaining a strong bonding to the face layer. This results in a lighter finished part weight, e.g. compared to traditional honeycomb structures.

MILLIFOAM® Rohacell SL thin foam sheets are characterized by a temperature stability of up to 180°C (356°F) with all common processes, including vacuum infusion, RTM, autoclave and hand lay-up. The high curing temperature allows excellent laminate properties and results in a significant reduction in total cycle time and faster component manufacturing.The thin MILLIFOAM® Rohacell SL foam sheets can be easily thermoformed and with 4a MILLIFOAM® Shaping, they can be provided as high-precision, pre-shaped and ready-to-use foam cores for complex geometries.

| Physical Characteristics | |||

|---|---|---|---|

| Format | MILLIFOAM® RHC71SL |

MILLIFOAM® RHC110SL |

|

| Plain Sheet | |||

| Length (mm) | 2500 | 2160 | |

| Width (mm) | 625 | 550 | |

| min. Thickness (mm) | 0.50 | 0.50 | |

| max. Thickness (mm) | 2.50 | 2.00 | |

| Standard thickness tolerance ±10%, other tolerances available on request. | |||

| Mechanical Characteristics | |||

|---|---|---|---|

| Property | MILLIFOAM® RHC71SL |

MILLIFOAM® RHC110SL |

|

| Density (kg/m³) | 75 (±15) | 110 (±15) | |

| Test Method: ISO 845 ASTM D 1622 | |||

| Compressive Strength (MPa) | 1.5 | 3.0 | |

| Test Method: ISO 844 ASTM D 1621 | |||

| Compressive Modulus (MPa) | 76 | 150 | |

| Test Method: ISO 844 ASTM D 1621 | |||

| Tensile Strength (MPa) | 3.7 | 6.0 | |

| Test Method: ISO 527-2 ASTM D 638 | |||

| Tensile Modules (MPa) | 120 | 202 | |

| Test Method: ISO 527-2 ASTM D 638 | |||

| Shear Strength (MPa) | 1.4 | 2.3 | |

| Test Method: DIN 53294 ASTM C 273 | |||

| Shear Modules (MPa) | 33 | 58 | |

| Test Method: DIN 53294 ASTM C 273 | |||

MILLIFOAM® PET

MILLIFOAM® Airex® T10 – The Premium Surface

With Airex® T10 we provide premium surface PET foam core with high specific properties.

Airex® T10 from 3A Composites Core Materials features a very homogenous density, cell structure and no weld lines. Due to its high mechanical properties and its outstanding fatigue strength, Airex® T10 brings high volume production of lightweight sandwich structures to a new level of properties and total costs.

In combination with our MILLIFOAM® technology, we provide Airex® T10 in a thickness range from 1,0mm to 3,0mm and with superior, dust-free surface quality.

MILLIFOAM® Airex® T10 features the well-known advantages of PET based Airex® core material such as recyclability, no water absorption, high processing temperatures up to 150°C (300°F), excellent long term stability up to 100°C (212°F) and a good adhesion (skin-to-core bond).

| Physical Characteristics | |||

|---|---|---|---|

| Format | MILLIFOAM® ARX100T10 |

||

| Plain Sheet | |||

| Length (mm) | 2440 | ||

| Width (mm) | 500 | ||

| min. Thickness (mm) | 1.00 | ||

| max. Thickness (mm) | 3.00 | ||

| Standard thickness tolerance ±10%, other tolerances available on request. | |||

| Mechanical Characteristics | |||

|---|---|---|---|

| Property | MILLIFOAM® ARX100T10 |

||

| Density (kg/m³) | 100 | ||

| Test Method: ISO 845 | |||

| Compressive Strength (MPa) | 1.2 | ||

| Test Method: ISO 844 | |||

| Compressive Modulus (MPa) | 105 | ||

| Test Method: ISO 844 | |||

| Tensile Strength (MPa) | 2.0 | ||

| Test Method: ASTM C 297 | |||

| Tensile Modules (MPa) | 150 | ||

| Test Method: ASTM C 297 | |||

| Shear Strength (MPa) | 1.1 | ||

| Test Method: ISO 1922 | |||

| Shear Modules (MPa) | 34 | ||

| Test Method: ISO 1922 | |||

MILLIFOAM® ArmaPET® Struct – The Green Solution

With ArmaPET® Struct we provide 100% recycled PET foam from Armacell.

ArmaPET® Struct provides a unique combination of material and processing properties, such as durability, elevated service temperature stability and excellent compatibility with most common resin and manufacturing methods.

Using 100% recycled PET as the base raw material, ArmaPET® supports industry environmental and sustainability directives and results in significant CO2 savings.

In combination with our MILLIFOAM® technology, we provide ArmaPET® Struct structural foam core in a standard thickness range from 1,0mm to 5,0mm and with superior, dust-free surface quality.

MILLIFOAM® ArmaPET® Struct withstands high processing temperatures of +150 °C (+302 °F) and has a good thermoformability behaviour.

| Physical Characteristics | ||||

|---|---|---|---|---|

| Format | MILLIFOAM® APS100GR |

MILLIFOAM® APS200GR |

MILLIFOAM® APS250GR |

|

| Plain Sheet | ||||

| Length (mm) | 2440 | 2440 | 2440 | |

| Width (mm) | 500 | 500 | 500 | |

| min. Thickness (mm) | 1.00 | 1.00 | 1.00 | |

| max. Thickness (mm) | 7.00 | 5.00 | 5.00 | |

| Standard thickness tolerance ±10%, other tolerances available on request. | ||||

| Mechanical Characteristics | |||

|---|---|---|---|

| Property | MILLIFOAM® APS100GR |

MILLIFOAM® APS200GR |

MILLIFOAM® APS250GR |

| Density (kg/m³) | 100 | 200 | 250 |

| Test Method: ISO 845 | |||

| Compressive Strength (MPa) | 1.5 | 4.0 | 5.3 |

| Test Method: ISO 844 | |||

| Compressive Modulus (MPa) | 160 | 230 | 270 |

| Test Method: ISO 844 | |||

| Tensile Strength (MPa) | 2.5 | 3.9 | 4.3 |

| Test Method: ASTM C 297 | |||

| Tensile Modules (MPa) | 120 | 235 | 270 |

| Test Method: ASTM C 297 | |||

| Shear Strength (MPa) | 0.75 | 1.75 | 2.0 |

| Test Method: ISO 1922 | |||

| Shear Modules (MPa) | 21 | 51 | 70 |

| Test Method: ISO 1922 | |||

MILLIFOAM® ArmaPET® Struct FR - The Green Fire-Retardant

With ArmaPET® Struct we provide 100% recycled PET foam from Armacell.

ArmaPET® Struct FR is a unique sustainable PET solution based on 100% recyclable material and fire-retardant, self-extinguishing properties. Designed for applications with particularly stringent fire protection requirements, ArmaPET® Struct FR is certified according to the relevant fire safety standards (e.g. NF F16-101, DIN 5510-2, EN 13823 and EN 45545-2).

In addition to its excellent fire safety performance, ArmaPET® FR provides a durable final product solution with high impact resistance for long-term performance. This makes it ideal for the use in transportation and construction.

MILLIFOAM® ArmaPET® Struct FR structural foam core is available in a standard thickness from 1,0mm to 4,0mm and with superior, dust-free surface quality.

| Physical Characteristics | |||

|---|---|---|---|

| Format | MILLIFOAM® APS100FR |

||

| Plain Sheet | |||

| Length (mm) | 2440 | ||

| Width (mm) | 500 | ||

| min. Thickness (mm) | 1.00 | ||

| max. Thickness (mm) | 4.00 | ||

| Standard thickness tolerance ±10%, other tolerances available on request. | |||

| Mechanical Characteristics | |||

|---|---|---|---|

| Property | MILLIFOAM® APS100FR |

||

| Density (kg/m³) | 100 | ||

| Test Method: ISO 845 | |||

| Compressive Strength (MPa) | 1.5 | ||

| Test Method: ISO 844 | |||

| Compressive Modulus (MPa) | 180 | ||

| Test Method: ISO 844 | |||

| Tensile Strength (MPa) | 2.4 | ||

| Test Method: ASTM C 297 | |||

| Tensile Modules (MPa) | 105 | ||

| Test Method: ASTM C 297 | |||

| Shear Strength (MPa) | 0.80 | ||

| Test Method: ISO 1922 | |||

| Shear Modules (MPa) | 20 | ||

| Test Method: ISO 1922 | |||

MILLIFOAM® Divicell® PL - The Excellent Core

With Diab’s Divinycell® PL we offer an all recyclable and excellent thermoplastic core material for composite sandwich structures.

Divinycell® PL is suitable for a variety of processing including infusion, prepreg and press bonding. The rigid foam provides a high shear strain, a low resin uptake, a good chemical resistance and allows high processing temperatures. Divinycell® PL is compatible with most common glues and resin systems and is an ideal core material in sandwich structures for the use in wind energy and industry.

In combination with our MILLIFOAM® technology we provide Divinycell® PL in a high-quality thickness from 0,5mm up to 5,0mm.

| Physical Characteristics | ||

|---|---|---|

| Format | MILLIFOAM® DIV105PL |

|

| Plain Sheet | ||

| Length (mm) | 2440 | |

| Width (mm) | 500 | |

| min. Thickness (mm) | 0.5 | |

| max. Thickness (mm) | 5.00 | |

| Standard thickness tolerance ±10%, other tolerances available on request. | ||

| Mechanical Characteristics | |||

|---|---|---|---|

| Property | MILLIFOAM® DIV105PL |

||

| Density (kg/m³) | 100 | ||

| Test Method: ISO 845 | |||

| Compressive Strength (MPa) | 1.5 | ||

| Test Method: ASTM D 1621 | |||

| Compressive Modulus (MPa) | 112 | ||

| Test Method: ASTM D 1621-B-73 | |||

| Tensile Strength (MPa) | 2.4 | ||

| Test Method: ASTM C 297 | |||

| Tensile Modules (MPa) | 110 | ||

| Test Method: ASTM C 297 | |||

| Shear Strength (MPa) | 0.95 | ||

| Test Method: ISO 1922 | |||

| Shear Modules (MPa) | 23 | ||

| Test Method: ISO 1922 | |||

MILLIFOAM® Gurit® Kerdyn™ - The Recycling Grade

With Gurit® Kerdyn™ Green we provide a 100% recycled PET based thermoplastic core material for sandwich structures.

Gurit® Kerdyn™ Green has been designed to respond to the growing need for structural core materials with stable properties and improved resin uptake performance. The foam grade is characterized by a good balance of mechanical properties, temperature resistance, density and cost for a wide range of applications and processes.

Applicable processing techniques include vacuum infusion, bonding, prepreg and thermoforming. Gurit® Kerdyn™ Green can be processed at high temperatures, offers an outstanding chemical resistance and is compatible with most commonly used resin systems.

In combination with our MILLIFOAM® technology we provide Gurit® Kerdyn™ Green in a thickness from 1,0mm up to 5,0mm and with superior, dust-free surface quality.

| Physical Characteristics | |||

|---|---|---|---|

| Format | MILLIFOAM® KER80GR |

MILLIFOAM® KER100GR |

|

| Plain Sheet | |||

| Length (mm) | 2440 | 2440 | |

| Width (mm) | 500 | 500 | |

| min. Thickness (mm) | 1.00 | 1.00 | |

| max. Thickness (mm) | 5.00 | 5.00 | |

| Standard thickness tolerance ±10%, other tolerances available on request. | |||

| Mechanical Characteristics | |||

|---|---|---|---|

| Property | MILLIFOAM® KER80GR |

MILLIFOAM® KER100GR |

|

| Density (kg/m³) | 80 | 100 | |

| Test Method: ISO 845 | |||

| Compressive Strength (MPa) | 0.86 | 1.30 | |

| Test Method: ASTM D 1621 | |||

| Compressive Modulus (MPa) | 74 | 91 | |

| Test Method: ISO 844 | |||

| Tensile Strength (MPa) | 1.54 | 1.82 | |

| Test Method: ASTM D 1623 | |||

| Tensile Modules (MPa) | - | 103 | |

| Test Method: ASTM D 1623 | |||

| Shear Strength (MPa) | 0.59 | 0.80 | |

| Test Method: ASTM C 273 | |||

| Shear Modules (MPa) | 18 | 25 | |

| Test Method: ISO 1922 | |||

MILLIFOAM® PPSU

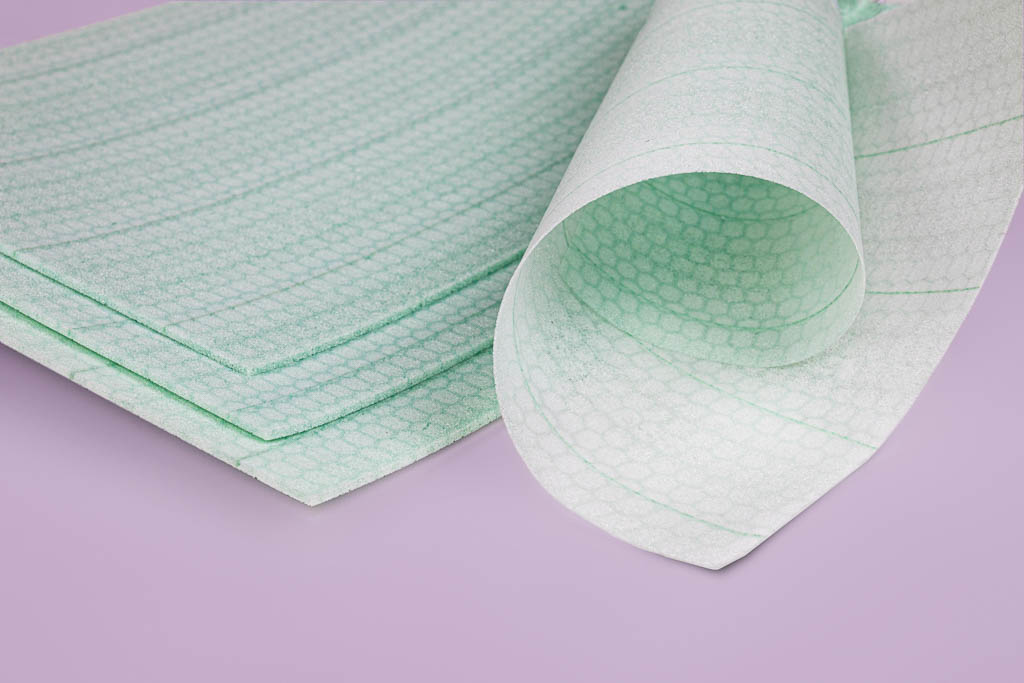

MILLIFOAM® Airex® TegraCore - The Fire Resistant

With Airex® TegraCore™ we offer a low density PPSU foam core with exceptional fire performance.

Airex® TegraCore™ from 3A Composites Core Materials is a closed-cell, ductile thermoplastic polymer foam based on polyphenylsulfone (PPSU).

The combination of excellent lightweight properties and retardant properties at low flammability, smoke, toxicity (FST) makes it the foam core of choice for demanding composite applications. It exceeds FAR 25.853 requirements and passes easily OSU heat release test.

MILLIFOAM® Airex® TegraCore™ thin foam sheets are characterized by a very low moisture absorption, very good chemical resistance against aerospace fluids and can be easily cut, bonded and thermoformed to complex shapes. They can be used for all common composite processes up to 180°C (355°F). Due to its PPSU polymer basis, MILLIFOAM® Airex® TegraCore™ is ideal for good sound and thermal insulation.

At least, MILLIFOAM® Airex® TegraCore™ has excellent dielectric properties, which makes it ideal for the use in our CIMERA® micro-sandwich radomes for 5G mmWave small cell antennas, SatCom and SatCom on the move applications.

| Physical Characteristics | |||

|---|---|---|---|

| Format | MILLIFOAM® TGC50R |

||

| Plain Sheet | |||

| Length (mm) | 2500 | ||

| Width (mm) | 590 | ||

| min. Thickness (mm) | 1.00 | ||

| max. Thickness (mm) | 6.00 | ||

| Standard thickness tolerance ±10%, other tolerances available on request. | |||

| Mechanical Characteristics | |||

|---|---|---|---|

| Property | MILLIFOAM® TGC50R |

||

| Density (kg/m³) | 55 | ||

| Test Method: ISO 845 | |||

| Compressive Strength (MPa) | 0.65 | ||

| Test Method: ASTM D1621 | |||

| Compressive Modulus (MPa) | 30 | ||

| Test Method: ASTM D 1621 | |||

| Tensile Strength (MPa) | 1.1 | ||

| Test Method: ASTM C297 | |||

| Shear Strength (MPa) | 0.75 | ||

| Test Method: ASTM C 273 | |||

| Shear Modules (MPa) | 9.3 | ||

| Test Method: ASTM C 273 | |||

MILLIFOAM® PESU

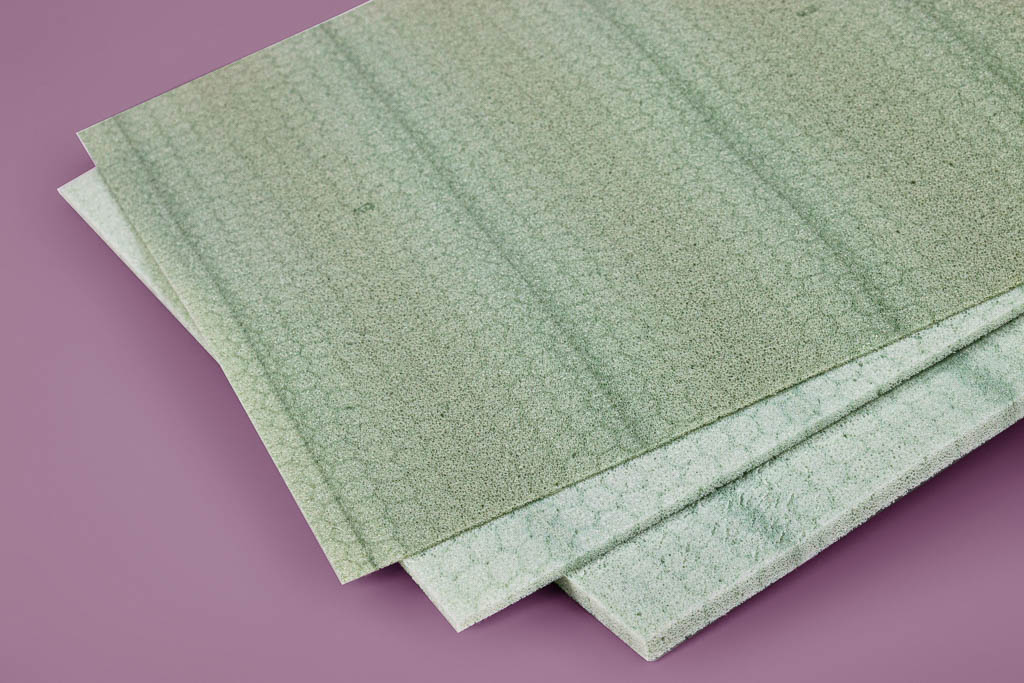

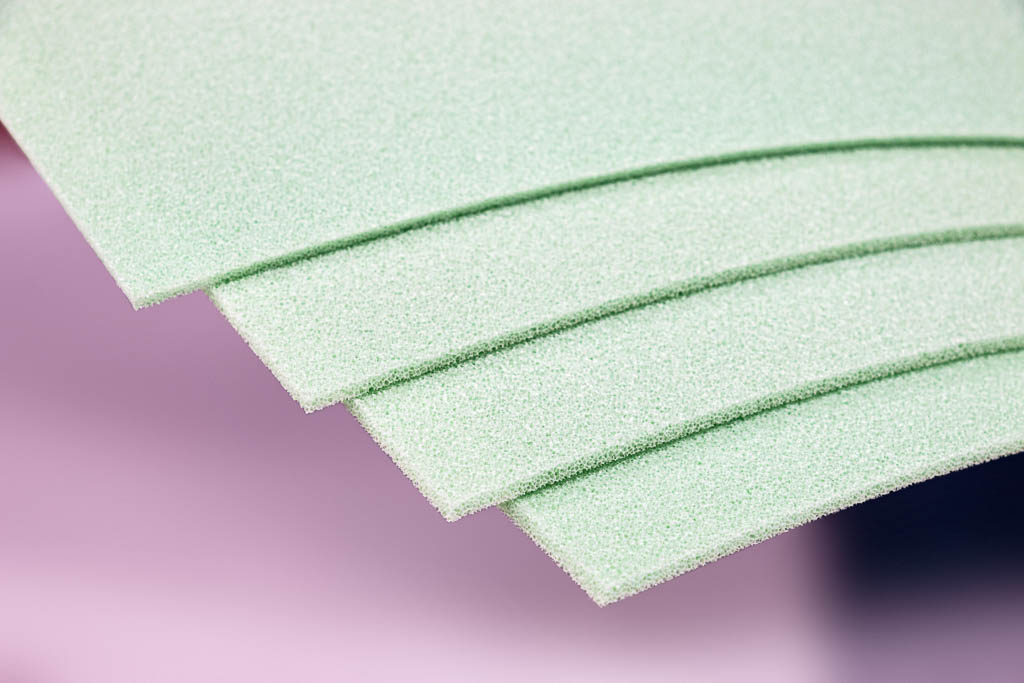

MILLIFOAM® Divicell®F - The Aircraft Interiors Standard

With Divinycell® F we provide Diab’s standard foam core for aircraft interiors.

Divinycell® F meets US and European regulatory requirements for commercial aircraft interiors and is qualified by AIRBUS under AIMS 04-11-000 and ABS5927.

Compatible with most common glue and resin systems, Divinycell® F is suitable for most common composite manufacturing processes up to 220°C (428°F). It offers excellent fire, smoke and toxicity (FST) properties and an exceptional OSU heat release performance.

In combination with our MILLIFOAM® technology, we provide Divinycell® F thin foam sheets in a superior surface quality and with well-known advantages of polyether sulfone (PESU) chemistry such as exceptional fatigue life, good chemical resistance and excellent heat ageing at 180°C (356°F). As core material in sandwich structures it is hot and cold formable and is fast and easy to process.

Moreover, MILLIFOAM® Divinycell® F can be ideally used as spacer in 5G antenna systems and as core layer in high frequency sandwich radomes for 5G mmWave small cell antennas, SatCom and SatCom on the move applications.

| Physical Characteristics | ||||

|---|---|---|---|---|

| Format | MILLIFOAM® DIV50F |

MILLIFOAM® DIV90F |

MILLIFOAM® DIV130F |

|

| Plain Sheet | ||||

| Length (mm) | 2440 | 2440 | 2440 | |

| Width (mm) | 610 | 533 | 560 | |

| min. Thickness (mm) | 1.00 | 0.50 | 1.00 | |

| max. Thickness (mm) | 3.00 | 4.00 | 3.00 | |

| Standard thickness tolerance ±10%, other tolerances available on request. | ||||

| Mechanical Characteristics | ||||

|---|---|---|---|---|

| Property | MILLIFOAM® DIV50F |

MILLIFOAM® DIV90F |

MILLIFOAM® DIV130F |

|

| Density (kg/m³) | 50 | 90 | 130 | |

| Test Method: ASTM D 1622 | ||||

| Compressive Strength (MPa) | 0.6 | 1.2 | 1.7 | |

| Test Method: ASTM D1621 | ||||

| Compressive Modulus (MPa) | 18 | 34 | 60 | |

| Test Method: ASTM C 365 | ||||

| Tensile Strength (MPa) | 1.9 | 2.8 | 3.3 | |

| Test Method: ASTM D 1623 | ||||

| Shear Strength (MPa) | 0.8 | 1.4 | 1.7 | |

| Test Method: ASTM C 273 | ||||

| Shear Modules (MPa) | 13.5 | 24 | 30 | |

| Test Method: ASTM C 273 | ||||

MILLIFOAM® PVC

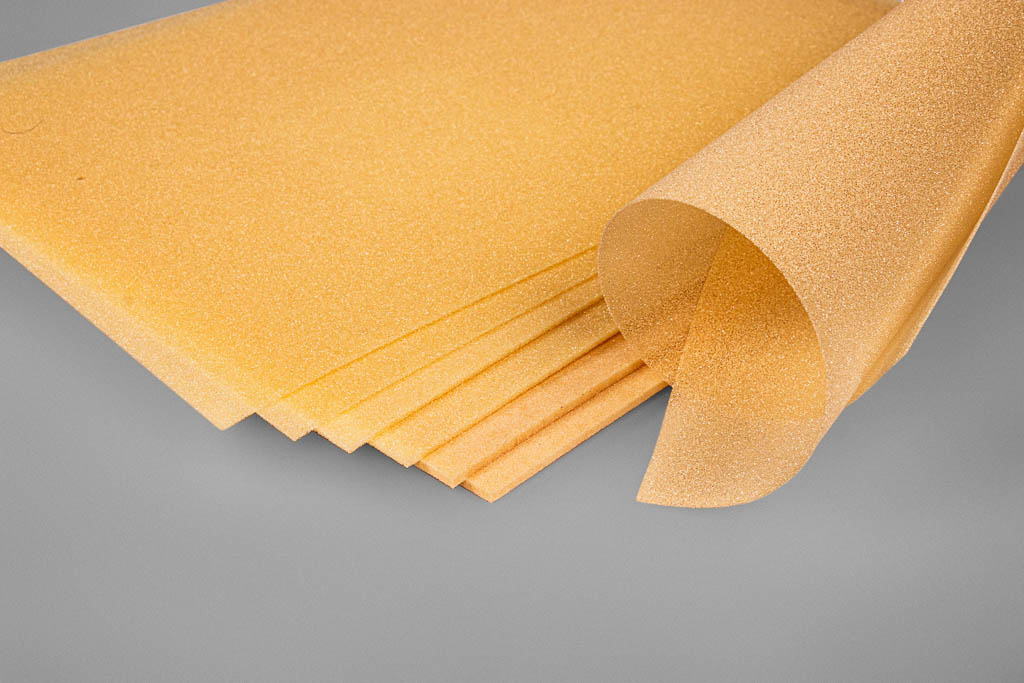

MILLIFOAM® Divicell®H - The Excellent Grade

With Divinycell® H we offer Diab’s unique PVC formulation with excellent mechanical properties to a low weight.

The unique polyvinylchloride (PVC) chemical structure of Divinycell® H is ideal for applications subjected to fatigue, slamming or impact loads. With its excellent mechanical properties to weight, Divinycell® H is widely used the foam of choice for marine, land transportation, wind energy, civil infrastructure and general industrial markets.

Divinycell® H is compatible with all commonly used resin and manufacturing systems. The foam has an excellent chemical resistance, a low water absorption and a good thermal/acoustic insulation behaviour. It can be processed at temperatures up to 90 °C, whereby maximum processing temperature depends on time, pressure and process conditions. It’s continuous operating temperature is typically -200 °C to +70 °C.

In combination with our MILLIFOAM® technology, we provide Divinycell® H structural PVC foam core in a standard thickness range from 0,5mm to 5,0mm and with superior, dust-free surface quality.

| Physical Characteristics | ||||

|---|---|---|---|---|

| Format | MILLIFOAM® DIV45H |

MILLIFOAM® DIV60H |

MILLIFOAM® DIV80H |

|

| Plain Sheet | ||||

| Length (mm) | 2440 | 2440 | 2440 | |

| Width (mm) | 610 | 610 | 610 | |

| min. Thickness (mm) | 0.50 | 1.00 | 0.50 | |

| max. Thickness (mm) | 4.50 | 4.00 | 5.00 | |

| Standard thickness tolerance ±10%, other tolerances available on request. | ||||

| Mechanical Characteristics | |||

|---|---|---|---|

| Property | MILLIFOAM® DIV45H |

MILLIFOAM® DIV60H |

MILLIFOAM® DIV80H |

| Density (kg/m³) | 48 | 60 | 80 |

| Test Method: ASTM D 1621 | |||

| Compressive Strengh (MPa) | 0.6 | 0.9 | 1.4 |

| Test Method: ASTM D1621 | |||

| Compressive Modulus (MPa) | 50 | 70 | 90 |

| Test Method: ASTM D 1621-B-73 | |||

| Tensile Strength (MPa) | 1.4 | 1.8 | 2.5 |

| Test Method: ASTM D 1623 | |||

| Tensile Modulus (MPa) | 55 | 75 | 95 |

| Test Method: ASTM D 1623 | |||

| Shear Strength (MPa) | 0.56 | 0.75 | 1.15 |

| Test Method: ASTM C 273 | |||

| Shear Modules (MPa) | 15 | 20 | 27 |

| Test Method: ASTM C 273 | |||

MILLIFOAM® MYcell® - The Common Grade

With MYcell® we offer a most common closed-cell structural PVC core material.

MYcell® from Maricell is suitable for all sandwich composite applications and has DNV-GL certifications, as well as flammability, smoke generation, drip properties and toxicity testing in accordance with DIN 5510-2. Fire classification AFNOR NF P 92.507 and smoke classification AFNOR NF F 16.101.

MILLIFOAM® MYcell® thin foam sheets are characterized by an excellent chemical resistance, thermal insulation capabilities and a negligible water absorption. The thin sheets have a low resin uptake and are compatible with all commonly used resin systems. The application range is very wide, including wind energy, marine, sports, transportation and industrial.

| Physical Characteristics | |||

|---|---|---|---|

| Format | MILLIFOAM® MAR60M |

MILLIFOAM® MAR80M |

|

| Plain Sheet | |||

| Length (mm) | 2450 | 2180 | |

| Width (mm) | 575 | 510 | |

| min. Thickness (mm) | 1.00 | 0.50 | |

| max. Thickness (mm) | 4.00 | 4.00 | |

| Standard thickness tolerance ±10%, other tolerances available on request. | |||

| Mechanical Characteristics | |||

|---|---|---|---|

| Property | MILLIFOAM® MAR60M |

MILLIFOAM® MAR80M |

|

| Density (kg/m³) | 60 | 80 | |

| Test Method: ISO 845 | |||

| Compressive Strengh (MPa) | 0.98 | 1.60 | |

| Test Method: ISO 844 | |||

| Compressive Modulus (MPa) | 67 | 97 | |

| Test Method: ISO 844 | |||

| Tensile Strength (MPa) | 1.82 | 2.74 | |

| Test Method: ISO 527-2 | |||

| Tensile Modulus (MPa) | 100 | 146 | |

| Test Method: ISO 527-2 | |||

| Shear Strength (MPa) | 0.79 | 1.20 | |

| Test Method: ISO 1922 | |||

| Shear Modules (MPa) | 21 | 30 | |

| Test Method: ASTM C 393 | |||

MILLIFOAM® Airex® - The universal Grade

With Airex® C70 we provide a closed-cell PVC foam grade that combines excellent strength and stiffness to weight ratio.

Airex® C70 from 3A Composites Core Materials has a negligible water absorption and provides an excellent resistance to chemicals. The rigid foam is compatible with most common resin and manufacturing processes and consequently ideally suited as core material for a broad range of sandwich structures subjected to static and dynamic loads.

The fine cell structure of Airex® C70 in combination with our unique MILLIFOAM® cutting technology offers thin sheets with an excellent bonding surface.

| Physical Characteristics | |||

|---|---|---|---|

| Format | MILLIFOAM® ARX55C70 |

MILLIFOAM® ARX75C70 |

|

| Plain Sheet | |||

| Length (mm) | 2450 | 2180 | |

| Width (mm) | 575 | 510 | |

| min. Thickness (mm) | 0.50 | 1.00 | |

| max. Thickness (mm) | 4.00 | 4.00 | |

| Standard thickness tolerance ±10%, other tolerances available on request. | |||

| Mechanical Characteristics | |||

|---|---|---|---|

| Property | MILLIFOAM® ARX55C70 |

MILLIFOAM® ARX75C70 |

|

| Density (kg/m³) | 60 | 80 | |

| Test Method: ISO 845 | |||

| Compressive Strengh (MPa) | 0.90 | 1.45 | |

| Test Method: ISO 844 | |||

| Compressive Modulus (MPa) | 69 | 104 | |

| Test Method: ISO 844 | |||

| Tensile Strength (MPa) | 1.3 | 2.0 | |

| Test Method: ISO 527 | |||

| Tensile Modulus (MPa) | 45 | 66 | |

| Test Method: ISO 527 | |||

| Shear Strength (MPa) | 0.85 | 1.2 | |

| Test Method: ISO 1922 | |||

| Shear Modules (MPa) | 22 | 30 | |

| Test Method: ASTM C 393 | |||

MILLIFOAM® PEI

MILLIFOAM® Divinicell® U - The Dielectric Core

With Divinicell® U we offer original high frequency foam grade from Diab.

| Physical Characteristics | ||||

|---|---|---|---|---|

| Format | MILLIFOAM® DIV60U |

MILLIFOAM® DIV80U |

||

| Plain Sheet | ||||

| Length (mm) | 2400 | 2440 | ||

| Width (mm) | 610 | 565 | ||

| min. Thickness (mm) | 0.50 | 0.50 | ||

| max. Thickness (mm) | 4.00 | 5.00 | ||

| Standard thickness tolerance ±10%, other tolerances available on request. | ||||

| Mechanical Characteristics | ||||

|---|---|---|---|---|

| Property | MILLIFOAM® DIV60U |

MILLIFOAM® DIV80U |

||

| Density (kg/m³) | 60 | 80 | ||

| Test Method: ASTM D 1622 | ||||

| Compressive Strength (MPa) | 0.7 | 1.1 | ||

| Test Method: ASTM D1621 | ||||

| Compressive Modulus (MPa) | 21 | 35 | ||

| Test Method: ASTM D 1621 | ||||

| Tensile Strength (MPa) | 2.1 | 2.8 | ||

| Test Method: ASTM D 1623 | ||||

| Shear Strength (MPa) | 0.8 | 1.0 | ||

| Test Method: ASTM C 273 | ||||

| Shear Modules (MPa) | 13 | 16 | ||

| Test Method: ASTM C 273 | ||||