MILLIFOAM® and CIMERA® cutouts tailored to your application

Introduction

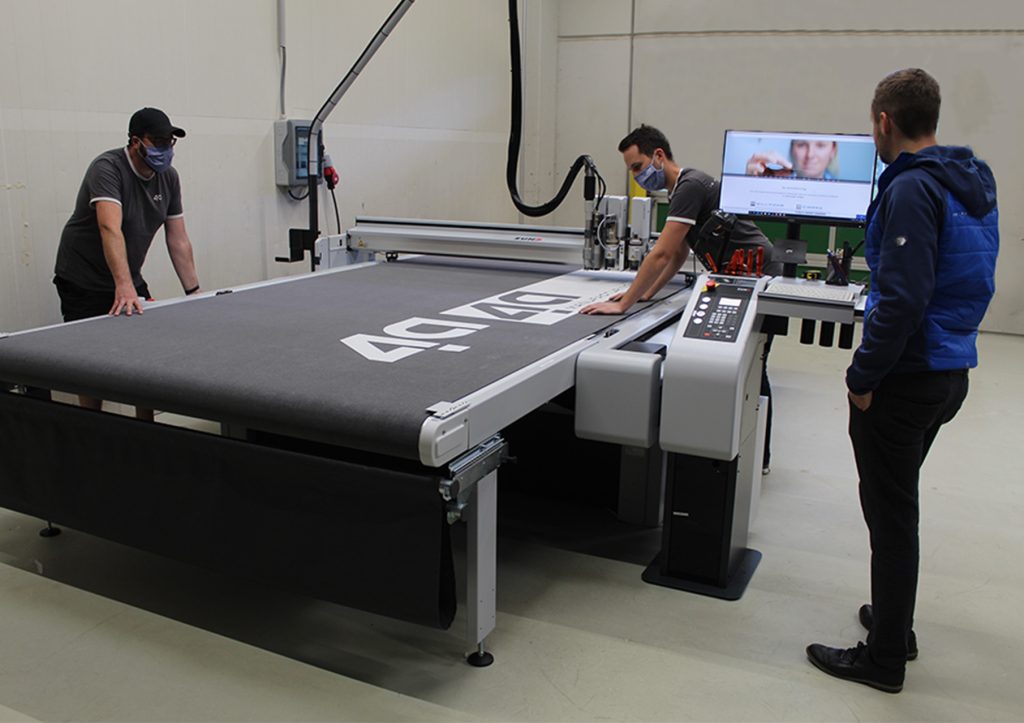

New lightweight application developments require the materials to be designed to specific and often complex geometries. Therefore, the demand for tailored and ready-to-use material solution has increased significantly over recent years. In order to meet customer’s specific requirements, modern cutting systems are used to produce geometrical shapes within in a reasonable time and with highest accuracy. With the 4a manufacturing new cutting system (see fi gure 1), customized cutouts can be easily produced for MILLIFOAM® thin hard foam sheets and for CIMERA® micro-sandwiches.

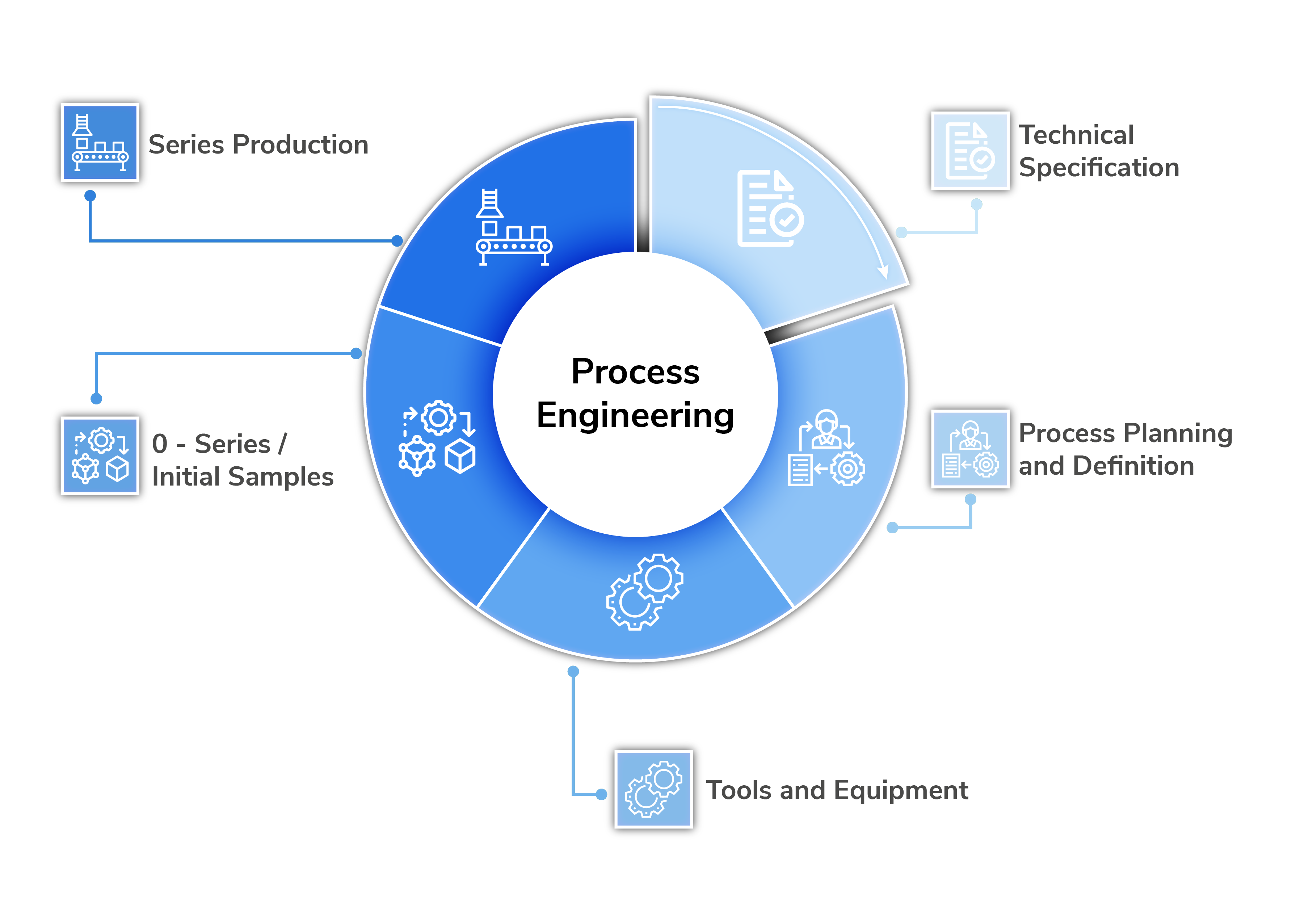

Figure 2: Schematic representation of 4a customized cutting service process.

Methods & Materials

As shown in figure 2, we support you on the way from the first prototype up to final geometry ready for serial production by providing a customized cutting service process. Therefore, a digital cutter with a working area of 2500x1800mm and equiped with different modules (e.g. universal, router, punch) is used to produce your specific cutouts quickly and in the required precision. Our cutting system is specially tuned to the finishing of a broad range of hard foam sheets and composite structures up to a thickness of approx. 50mm.

Figure 3: Tailored cutout geometries for MIllifoam and CImera

Benefits

You benefit from “ready-to-use” parts and tailored solutions, which are fitted to your specific requirements (see fi gure 3). Furthermore, you receive your final part from one single source, which simplifies your internal workflow and increases your economic efficiency. This means, that you save time and money by eliminating additional processing steps in your production. Finally, you benefit from a strong partner with long-term experience on your side.